Progressive cavity pumps are widely used in various industries due to their ability to handle viscous fluids and provide a steady flow. Understanding the diagrams associated with these pumps is crucial for several stakeholders. This article explores who uses progressive cavity pump diagrams and the importance of these visual aids.

Understanding Progressive Cavity Pumps

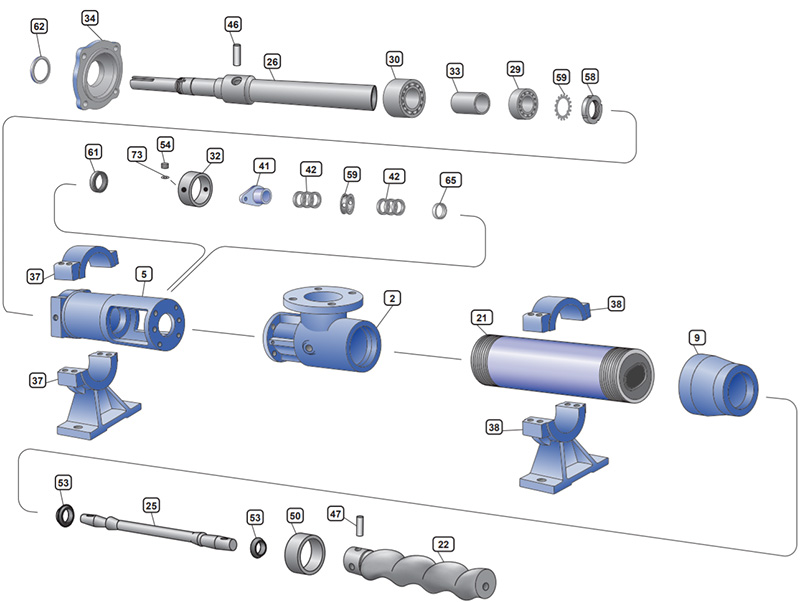

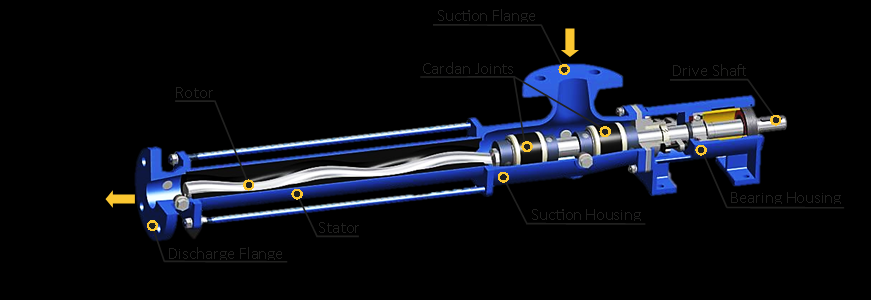

A progressive cavity pump consists of a helical rotor and a stator. This design allows for the efficient movement of fluids, making it ideal for applications involving thick or viscous materials. The pump’s diagram illustrates its components and how they interact, providing essential information for users.

Key Users of Progressive Cavity Pump Diagrams

Several groups benefit from understanding progressive cavity pump diagrams:

1. Engineers and Designers

Engineers and designers utilize pump diagrams during the development phase of projects. These diagrams help in:

- Visualizing the pump’s operation

- Understanding the flow dynamics

- Identifying potential design improvements

2. Maintenance Technicians

Maintenance technicians rely on these diagrams for troubleshooting and repairs. They use the diagrams to:

- Locate components for maintenance

- Understand the pump’s operational mechanics

- Diagnose issues based on the flow path and component interactions

3. Operators

Operators who work with progressive cavity pumps use diagrams for day-to-day operations. Key uses include:

- Familiarizing themselves with the pump’s layout

- Ensuring proper setup and alignment

- Monitoring performance and identifying irregularities

4. Educators and Students

In educational settings, progressive cavity pump diagrams serve as valuable teaching tools. They help students and trainees to:

- Grasp fundamental concepts of pump mechanics

- Engage in hands-on learning through diagram interpretation

- Prepare for careers in engineering and process industries

Importance of Progressive Cavity Pump Diagrams

The significance of these diagrams extends beyond mere representation. They serve several functions:

Visual Clarity

Diagrams provide a clear visual representation of complex mechanisms, making it easier for users to understand the intricacies of pump operation.

Standardization

Having standardized diagrams helps ensure that everyone involved in the process—from designers to operators—has a consistent understanding of the pump’s structure and function.

Training and Safety

Diagrams are essential for training new employees, ensuring they understand the operational aspects and safety protocols associated with the pumps. This knowledge is crucial for preventing accidents and ensuring efficient operations.

Conclusion

Progressive cavity pump diagrams are invaluable tools across multiple sectors. Engineers, maintenance technicians, operators, and educators all benefit from these visual aids. By enhancing understanding and facilitating communication, diagrams play a vital role in the effective use and maintenance of progressive cavity pumps, ultimately contributing to operational efficiency and safety.