Maintaining your Seepex BN pump is crucial for ensuring its longevity and optimal performance. A well-maintained pump not only functions efficiently but also reduces the risk of unexpected failures and costly repairs. This article outlines key maintenance practices, common issues to watch for, and tips for effective care.

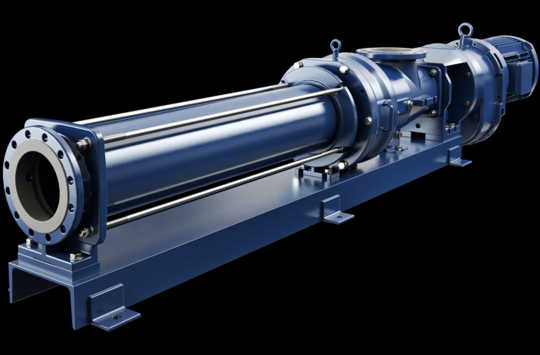

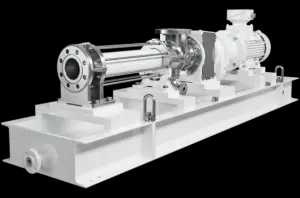

Understanding the Seepex BN Pump

The Seepex BN pump is a progressive cavity pump known for its reliability and versatility in handling various fluids. It is often used in industries such as wastewater treatment, food processing, and chemical manufacturing. Understanding the components and functioning of the pump is essential for effective maintenance.

Key Components

- Stator: The elastic part that houses the rotor and helps create the pumping action.

- Rotor: The helical component that rotates within the stator to move the fluid.

- Drive Shaft: Connects the motor to the rotor, transmitting the necessary power.

- Bearing Housing: Supports the rotor and ensures smooth operation.

- Seals: Prevent leaks and protect the internal components from contamination.

Importance of Regular Maintenance

Regular maintenance of your Seepex BN pump can lead to several benefits:

- Extended Lifespan: Proper care minimizes wear and tear, prolonging the pump’s operational life.

- Increased Efficiency: A well-maintained pump operates at peak efficiency, reducing energy costs.

- Reduced Downtime: Early detection of potential issues prevents unexpected breakdowns.

- Improved Safety: Regular inspections help identify hazards, ensuring a safe working environment.

Maintenance Checklist

Daily Checks

- Visual Inspection: Look for any signs of leaks or unusual noises during operation.

- Temperature Monitoring: Ensure the pump is operating within the recommended temperature range.

Weekly Checks

- Fluid Levels: Check the lubricant levels in the bearing housing to prevent overheating.

- Seal Condition: Inspect seals for wear and tear to avoid leaks.

Monthly Checks

- Rotor and Stator Inspection: Examine the rotor and stator for signs of wear, such as scoring or distortion.

- Belt Tension: If applicable, ensure that drive belts are properly tensioned to avoid slippage.

Quarterly Checks

- Alignment Verification: Check the alignment of the drive shaft to prevent undue stress on the bearings.

- Bearing Inspection: Inspect bearings for wear and replace them if necessary.

Common Issues and Troubleshooting

Understanding common issues can help you address problems before they escalate. Here are a few typical problems and their potential solutions:

Low Flow Rate

- Possible Causes: Clogged inlet, worn rotor or stator.

- Solutions: Clean the inlet and inspect the rotor and stator for damage. Replace components as needed.

Excessive Vibration

- Possible Causes: Misalignment, unbalanced rotor, or worn bearings.

- Solutions: Check alignment and balance, and inspect bearings for wear.

Unusual Noises

- Possible Causes: Cavitation or foreign objects in the pump.

- Solutions: Investigate for cavitation issues, such as low suction pressure, and remove any foreign objects.

Tips for Effective Maintenance

To ensure the longevity and performance of your Seepex BN pump, consider the following tips:

- Keep a Maintenance Log: Document all maintenance activities to track performance and identify trends.

- Train Your Staff: Ensure that operators are trained in proper handling and basic troubleshooting techniques.

- Use Quality Parts: When replacing components, always choose genuine Seepex parts to maintain compatibility and performance.

- Schedule Regular Servicing: Work with a qualified technician to perform comprehensive inspections and service.

Conclusion

Proper maintenance of your Seepex BN pump is essential for its reliability and efficiency. By following a consistent maintenance schedule, addressing common issues promptly, and training your staff effectively, you can maximize the lifespan and performance of your pump. Investing time and resources into maintenance will pay off in reduced downtime and enhanced operational efficiency.