Pin Bush Coupling Procurement

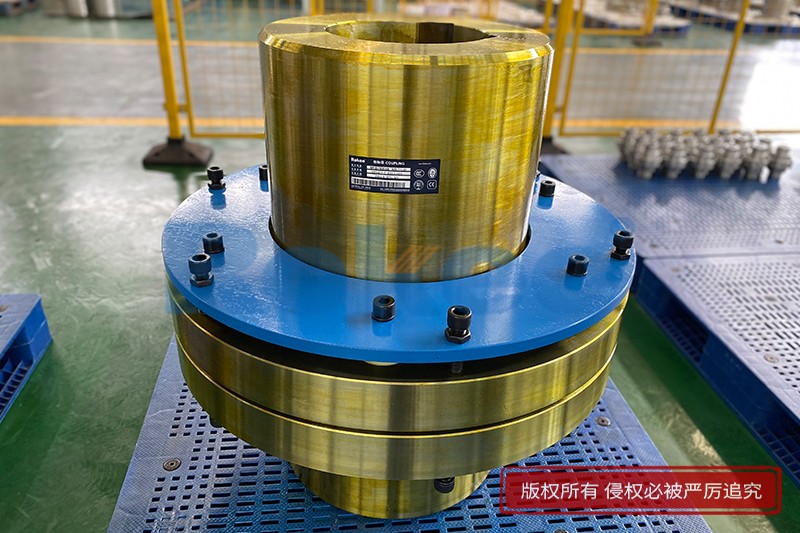

Pin Bush Coupling Procurement The pin and bush couplings accept parallel, angular and axial misalignment and can provide considerable torsional flexibility. The flexible pin gear coupling is designed with non-metallic flexible pin, two toothed semi-couplings and a toothed sleeve ring with an outer ring. It uses non-metallic flexible deformation to transfer torque and cushion shock […]

Pin Bush Coupling Procurement Read More »