In industrial applications, the reliable operation of pumps is crucial for maintaining efficiency and productivity. One of the leading manufacturers of precision pumps is Netzsch, known for their innovative solutions tailored to various sectors, including food processing, chemical manufacturing, and wastewater treatment. Central to maintaining these pumps is the Netzsch pump parts list, which details all necessary components for repair and maintenance.

The Importance of Reliable Pump Operation

Pumps play a vital role in many processes, transferring fluids from one location to another. Whether dealing with viscous materials, abrasive substances, or sensitive liquids, the performance of a pump can significantly affect operational workflows. A failure in the pump system can lead to costly downtime, interrupted service, and potential damage to equipment.

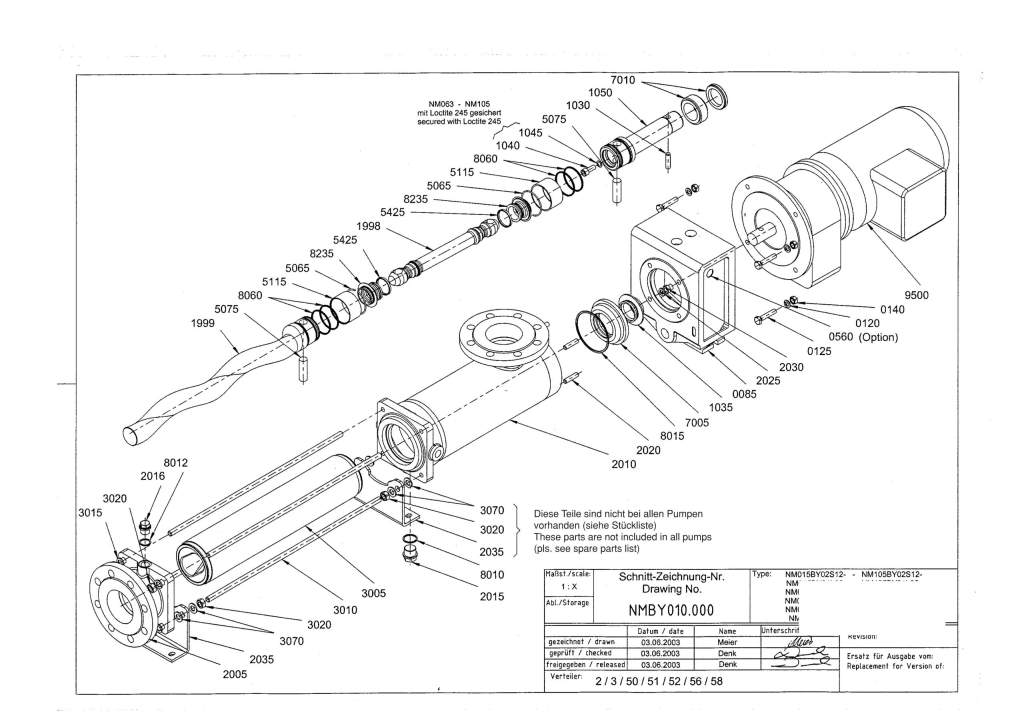

This is where understanding the Netzsch pump parts list becomes essential. Having access to detailed information about available parts helps technicians quickly identify replacements or components needed for maintenance, ensuring that pumps can be restored to full functionality promptly.

Components of Netzsch Pumps

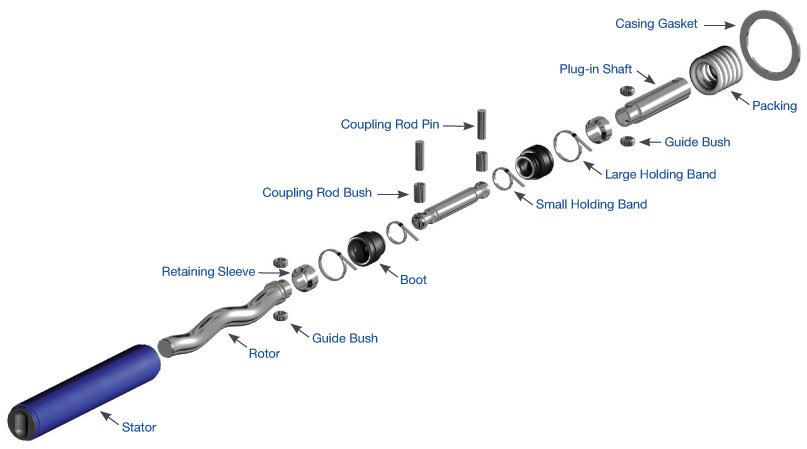

Netzsch offers a range of pump types, including rotary lobe pumps, progressing cavity pumps, and peristaltic pumps. Each type comprises various components, all of which are listed in the Netzsch pump parts list. Common components include:

- Rotors and Stators: In rotary pumps, these parts are critical for creating the pumping action. The rotor’s design directly influences the pump’s efficiency and capability to handle different materials.

- Seals: Proper sealing is vital to prevent leaks and ensure operational safety. Various seal types are available, depending on the application.

- Bearings: Bearings support the rotating components and reduce friction, which is essential for efficient operation.

- Housings: The housing encloses the pump mechanism, providing protection and support for the operational parts.

- Drive Systems: Different drive options, including electric motors and hydraulic systems, are listed to cater to diverse operational requirements.

Having a complete Netzsch pump parts list enables users to identify the specific parts applicable to their pumps, facilitating easier ordering and maintenance planning.

Benefits of Maintaining an Updated Parts Inventory

An updated Netzsch pump parts list not only assists in immediate repairs but also helps in strategic planning. Maintaining an inventory of essential spare parts can bring several benefits:

1. Reduced Downtime

With immediate access to critical components, technicians can minimize the time spent on repairs. This ensures that production processes remain uninterrupted, protecting operational efficiency.

2. Cost-Effectiveness

Investing in spare parts in advance can lead to cost savings. Emergency orders often come with higher prices and shipping costs, whereas planned purchases allow for better budgeting and negotiation.

3. Improved Safety

Regular maintenance using genuine Netzsch parts ensures the pumps are functioning correctly, reducing the likelihood of accidents and equipment failure that could pose safety risks.

Challenges in Pump Maintenance

While having a Netzsch pump parts list is beneficial, there are challenges that maintenance teams may face. The specificity of parts required for various models can sometimes result in confusion if the wrong components are ordered. Additionally, the technical knowledge needed to assess which parts are necessary can vary among maintenance personnel.

To mitigate these challenges, training programs are essential. Providing staff with in-depth knowledge about Netzsch pumps and their components will empower them to make informed decisions regarding maintenance and repairs.

The Role of Technology in Parts Management

In today’s digital age, technology plays a pivotal role in parts management. Many companies are utilizing inventory management systems that integrate with the Netzsch pump parts list. Such systems allow for tracking part usage, predicting when replacements may be needed, and automating reorder processes.

Furthermore, online platforms provided by manufacturers enable users to access the latest parts lists, specifications, and availability in real time. This accessibility significantly enhances the efficiency of maintenance operations.

Conclusion

In summary, understanding the Netzsch pump parts list is fundamental for maintaining the reliability and efficiency of Netzsch pumps across various industries. By ensuring access to the necessary components and maintaining a well-planned inventory, organizations can reduce downtime, improve safety, and enhance operational cost-effectiveness.

With technological advancements and continuous training, maintenance teams can navigate the complexities of pump maintenance more effectively, leading to streamlined operations and improved productivity. As industries continue to evolve, the importance of reliable pump systems and their efficient management will remain a key factor in achieving long-term success.