When it comes to industrial pumping applications, one of the most versatile and reliable options is the progressing cavity pump. Also known as a cavity pump or a Moineau pump, this positive displacement pump is well-suited for handling a wide range of viscous, abrasive, and shear-sensitive fluids. From wastewater treatment to oil and gas production, progressing cavity pumps are a popular choice across many industries.

However, with so many progressing cavity pump manufacturers out there, how can you ensure you’re selecting a high-quality, reliable provider? Here are some key factors to consider when identifying quality cavity pump manufacturers:

Experience and Expertise

One of the most important indicators of a quality progressing cavity pump manufacturer is their level of experience and technical expertise. Look for a company that has been in the pumping industry for many years and has a proven track record of successful installations across diverse applications.

Reputable progressing cavity pump manufacturers will have a deep understanding of pump design, materials, and performance characteristics. They should be able to provide in-depth technical guidance to help you select the optimal pump configuration for your specific needs.

Additionally, quality manufacturers will typically have a team of knowledgeable engineers, application specialists, and field technicians to support customers throughout the entire product lifecycle – from initial design and selection to installation, commissioning, and ongoing maintenance.

Product Quality and Reliability

When evaluating potential progressing cavity pump suppliers, it’s crucial to assess the quality and reliability of their products. Look for manufacturers that use high-grade materials and precision engineering techniques to ensure long service life and consistent performance.

Reputable providers will subject their pumps to rigorous testing and quality control measures to verify flow rate, pressure, efficiency, and other critical parameters. They should also offer comprehensive warranties that give you peace of mind about the dependability of their equipment.

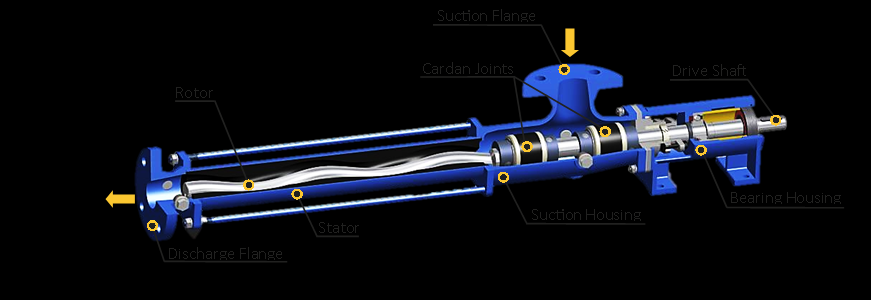

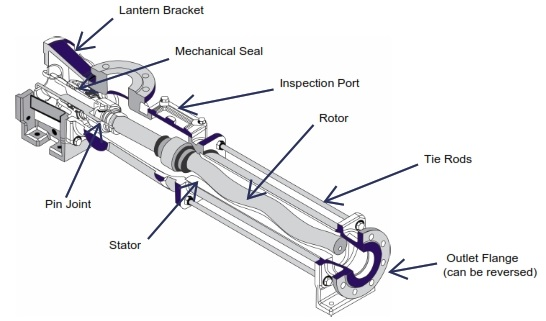

Beyond the pumps themselves, quality manufacturers will provide durable, well-engineered components such as stators, rotors, seals, and drive shafts. These parts should be designed for easy maintenance and replacement to minimize downtime.

Customization and Flexibility

While standardized progressing cavity pump models can be suitable for many applications, the best manufacturers will offer a high degree of customization to meet your unique requirements. Look for providers that can modify pump dimensions, materials, and configurations to handle your specific fluid properties, flow rates, and operating conditions.

Quality progressing cavity pump manufacturers will also have the flexibility to integrate their equipment with your existing infrastructure, whether that means custom mounting arrangements, driver options, or interface connections. This level of customization can be crucial for optimizing pump performance and ensuring a seamless installation.

Additionally, reputable providers will maintain an extensive inventory of spare parts and offer rapid turnaround on custom orders to minimize your downtime.

Local Support and Service

When selecting a progressing cavity pump manufacturer, it’s important to consider the level of local support and service they can provide. Look for a company with a network of regional sales offices, service centers, and authorized distributors to ensure prompt assistance whenever you need it.

Quality manufacturers will offer comprehensive after-sales support, including installation supervision, commissioning, preventive maintenance programs, and responsive repair services. They should also provide thorough training and documentation to empower your own maintenance teams.

By choosing a progressing cavity pump manufacturer with a strong local presence, you can ensure quick access to expertise, spare parts, and field support – crucial for minimizing downtime and maintaining optimal pump performance.

In conclusion, identifying quality progressing cavity pump manufacturers requires careful evaluation of their experience, product quality, customization capabilities, and local support. By prioritizing these key factors, you can ensure you select a reliable, high-performing pumping solution that meets the unique demands of your application.