- Previous blog

- Next blog

- Huyett Marketing Department

- 03/18/2021

- Updated: 09/14/2023

Shaft collars are machine components found in many power transmission applications, most notably motors and gear boxes. They are used as mechanical stops, locating components, or bearing faces. They install easily and are available in a variety of styles and materials.

What are Shaft Collars Used For?

Shaft collars, or shaft collar clamps, are used to locate, space, and secure components on a shaft by fastening axially or radially to a shaft. They are used as spacers and stroke limiters as well as retaining sprocket hubs, bearings, and shaft protectors.

What are Some Design Considerations for Shaft Collars?

There are a handful of factors to consider when selecting the right shaft collar for your application including materials, installation and disassembly, precision, clamping force, finish, bore size, and bore style.

Materials

Materials are always a consideration for any application when selecting a fastener, and shaft collars are no exception. They are crafted from aluminum, carbon steel, and stainless steel.

- Aluminum shaft collars are light, durable, and corrosion resistant. They also have excellent holding power, making them a popular choice for many applications.

- Carbon steel shaft collars offer a durable, economical solution for bearing retention, spacing, and more. However, they are more susceptible to corrosive environmental conditions. Some carbon steel shaft collars are zinc plated or coated with a black oxide finish for added protection.

- Stainless steel shaft collars excel in corrosion resistance against salt water, acids, and other corrosive agents. Stainless steel shaft collars have similar holding power as carbon steel collars, however, weakness can lie in the cap screws. If the cap screws holding the clamp together are made of an inferior material, the holding power of the collar can be compromised and premature failure can occur. This can be avoided by using hardware that is the same grade as the collar.

Finish

Carbon steel collars are offered in black oxide and zinc plating. Zinc plating offers the most protection against corrosive elements. However, the smooth finish reduces the collar’s holding power. Black oxide provides less protection when compared to zinc plating. However, its rough finish provides more holding power than zinc plating.

For more information on how finishes protect metals, visit our

Introduction to Metal Finishes guide.

Introduction to Metal Finishes guide.

Precision

Precision is the relation of the shaft collar face and its perpendicularity to the collar bore. A groove is machined into the face of the collar to indicate perpendicular precision as well as which side of the collar is load bearing. The load bearing side of the collar should be positioned against accompanying gear, sprocket, hub, or pulley. If a collar with a precision face is not used, pressure against the collar will be unevenly distributed causing the collar to “walk” off the shaft.

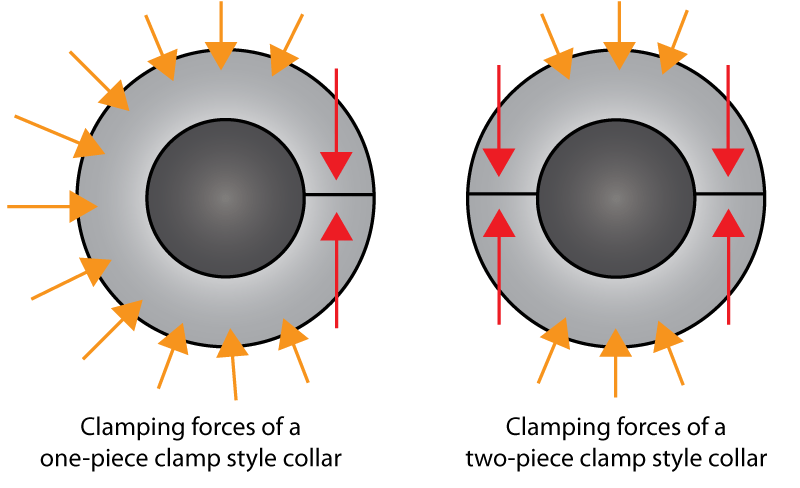

Clamping Force

Clamping force between different shaft collar types varies. Solid, set screw shaft collars provide the lowest amount of holding power through the single set screw that engages the mating shaft. A single split provides more power by drawing the clamp body tight against the mating shaft. A double split provides slightly more holding power than a single split and distributes holding power uniformly around the shaft. Single- and double-split collars hold the greatest clamping force. For applications that require high axial loads, threaded bores are available.

Bore Size

Bore size references the inner diameter of the shaft collar. If the bore size is too big, the collar will not provide adequate clamping force on intended shaft and may prematurely release. Conversely, if the bore is too small, it will not fit on the shaft.

Bore Style

Bore style refers to the inner diameter profile of the collar, which includes the type of bore and whether the bore is threaded. Round is the most popular bore type. However, collars with hex bores do exist for applications using hex shafts. Threaded and smooth bores are also features for consideration when selecting a collar. Threaded bores provide positive engagement through the threads, promoting more holding force than smooth bore shaft collars.

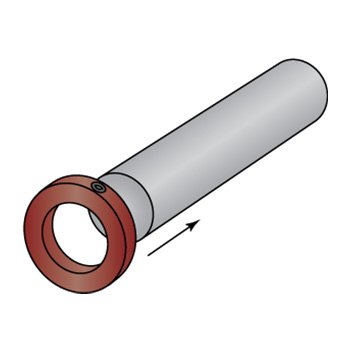

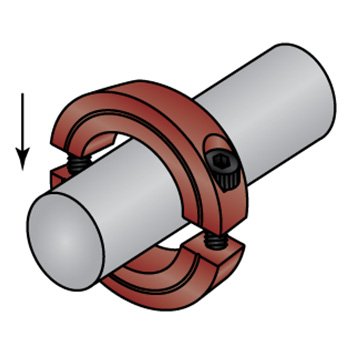

Installation

Shaft collars will either be installed axially or radially, depending on their design. Consider whether you will have the space for one installation style over another and, if you must choose one, if a collar with that style will support the clamping force and other requirements for your application.

Axial

Radial

Measurements

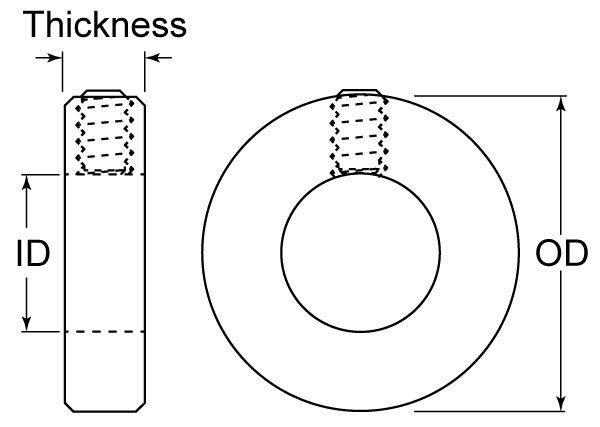

Regardless of the type of shaft collar you plan to use, there are three key measurements to take that will help you determine if the collar is the correct size for your application:

- Inside diameter (min. and max.)

- Outside diameter (min. and max.)

- Thickness

The example below features a set screw collar, but the noted dimensions apply to other types of collars as well. The main difference is that single- and double-split collars will have a minimum and maximum inside and outside diameters since the splits will close to a certain degree.

Different Types of Shaft Collars

There are a wide variety of shaft collars to choose from. The most popular styles are set screw, single-split, double-split, and threaded. Each style has their own unique benefits in a given application.

What are Set Screw Shaft Collars?

Single-split shaft collars are a single piece shaft collar without splits or relief cuts. They feature a set screw at the outer face of the collar that is perpendicular to the inner diameter of the collar. This set screw is tightened until it engages the mating shaft to hold the collar securely in place. Holding power for set screw collars is focused where the set screw engages the shaft. The set screw can damage shafts if the shaft material is softer than the screw. This also affects positioning of the collar since small adjustments are near impossible as the set screw tends to draw itself back to its original location.

- Common Names: Set Screw Collar; Solid Clamping Collar; Set Shaft Collar

- Applicable Standards: There are no applicable standards; however, most manufacturers follow similar designs.

- Fabrication: Material is bored and single‑point faced.

- How to Identify: Bore (inside diameter); solid one‑piece design with set screw.

- Common Uses: Used as mechanical stops, locating components, and bearing faces. Found in applications such as sprocket hubs, bearing holders, and shaft protectors.

- Comments: Shaft must be unhardened and softer than the set screw. Marring on the shaft can occur. Lowest cost.

Installation

Set collars are economical, installed axially, and are used on unhardened shafts. They are secured with a set screw.

- Back the set screw out so that it does not protrude into the inner diameter of the shaft collar.

- Slide the collar over the end of the mating shaft.

- Position the collar to the desired location.

- Tighten the set screw until it engages the mating shaft.

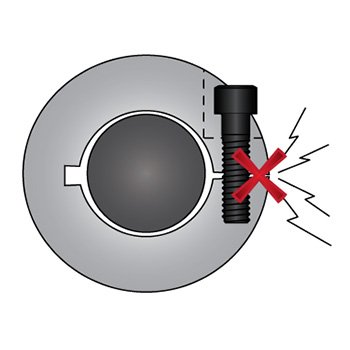

- Do not over tighten the set screw as damage to the shaft and collar can result.

- To remove, loosen the set screw and slide the collar off the shaft.

What are Single-Split Shaft Collars?

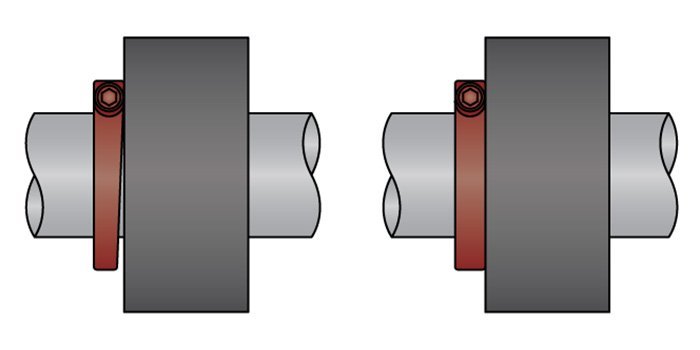

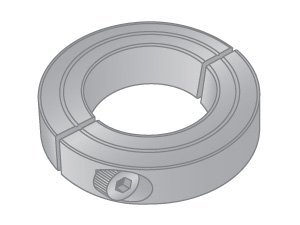

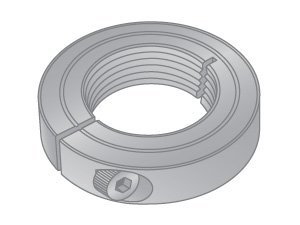

Single-split shaft collars, also known as single piece shaft collars, have a single slit opening that is closed with the integrated hex socket cap screw. The screw tightens around the shaft without causing damage or altering its face. Single-split collars are only installed axially onto a shaft, and while economical and simple to use, their holding power is not as uniformly distributed when compared to double-split collars. As such, single-split collars are great for non‑rotating assemblies.

- Common Names: Split Hub Collar; Clamp Collar

- Applicable Standards: There are no applicable standards; however, most manufacturers follow similar designs.

- Fabrication: Material is bored and single‑point faced.

- How to Identify: Bore (inside diameter); one‑piece design with a cut through one side and a relief cut opposite; clamped with a cap screw.

- Common Uses: Used as mechanical stops, locating components, and bearing faces. Found in applications such as sprocket hubs, bearing holders, and shaft protectors.

- Comments: Must be installed over the end of the shaft while it is disassembled from other components. Relief cut enables easy tightening.

Installation

Single‑split collars provide better holding power than set collars and must be installed axially.

- Loosen the integrated socket head cap screw to allow the collar to slightly expand during installation.

- Slide the collar over the end of the mating shaft.

- Position the collar to the desired location.

- Tighten the screw until the collar is firmly tightened around the shaft.

- Do not over tighten. The gap in single-split collars should not be closed.

- To remove, loosen cap screw and slide the collar off the shaft

Over-Tightened Shaft Collar

What are Double-Split Shaft Collars?

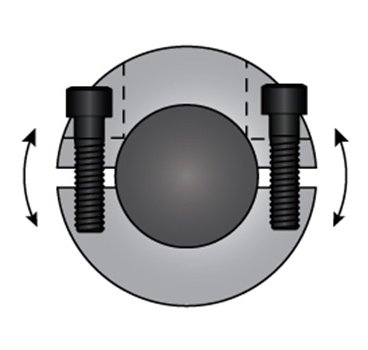

Double-split shaft collars, or two piece shaft collars, are a two piece collar held together by two integrated socket cap screws. These collars can be installed either radially or axially on a shaft. Due to their two piece design, double-split collars provide more uniform holding power and are more balanced making them suitable for rotating assemblies.

- Common Names: Two‑piece Clamp‑on Collar

- Applicable Standards: There are no applicable standards; however, most manufacturers follow similar designs.

- Fabrication: Material is bored and single‑point faced.

- How to Identify: Bore (inside diameter); two‑piece design with a cap screw on each side.

- Common Uses: Used as mechanical stops, locating components, and bearing faces. Found in applications such as sprocket hubs, bearing holders, and shaft protectors.

- Comments: Can be installed in‑line without disassembling component parts.

Installation

Double‑split collars install easily without disassembling machinery and provide excellent clamping power.

- Remove both integrated socket head cap screws and separate the two pieces of the collar. If installing radially, steps for installing a single-split collar can be followed.

- Position the separate collar pieces adjacent to each other, aligning the mating screw holes onto the intended shaft.

- Reinsert the cap screws into the collar and tighten until the screw threads engage the collars.

- With the collar as one piece, position it to the desired location and finish tightening the cap screws.

- Alternate tightening the screws so the collar body closes around the shaft uniformly.

- Do not over tighten the screws. The gaps between the two collar sections should not be closed.

- To remove, loosen or remove the cap screws from the collar to disengage the collar from the shaft.

What are Threaded Shaft Collars?

Threaded shaft collars can be both

single-split and

double-split and as such can be installed both axially and radially. The internal threads of the clamp allow for more precise positioning along a threaded shaft, as well as enhanced support of high axial loads. In addition, the threads act as a positive mechanical stop.

single-split and

double-split and as such can be installed both axially and radially. The internal threads of the clamp allow for more precise positioning along a threaded shaft, as well as enhanced support of high axial loads. In addition, the threads act as a positive mechanical stop.

- Common Names: Threaded Clamp Collar

- Applicable Standards: There are no applicable standards; however, most manufacturers follow similar designs.

- Fabrication: Material is bored and single‑point faced.

- How to Identify: Fine or coarse threaded bore (inside diameter); single‑ or double‑split design.

- Common Uses: Used as mechanical stops, locating components, and bearing faces. Found in applications such as sprocket hubs, bearing holders, and shaft protectors.

- Comments: Available in fine or coarse threads. Relief cut enables easy tightening.

The Bottom Line

Looking for more information about shaft collars? Visit our

Product FAQs page or

contact us to speak with our friendly and knowledgeable Sales team!

Product FAQs page or

contact us to speak with our friendly and knowledgeable Sales team!