- Previous blog

- Next blog

- Huyett Marketing Department

- 11/04/2020

Bright Steels

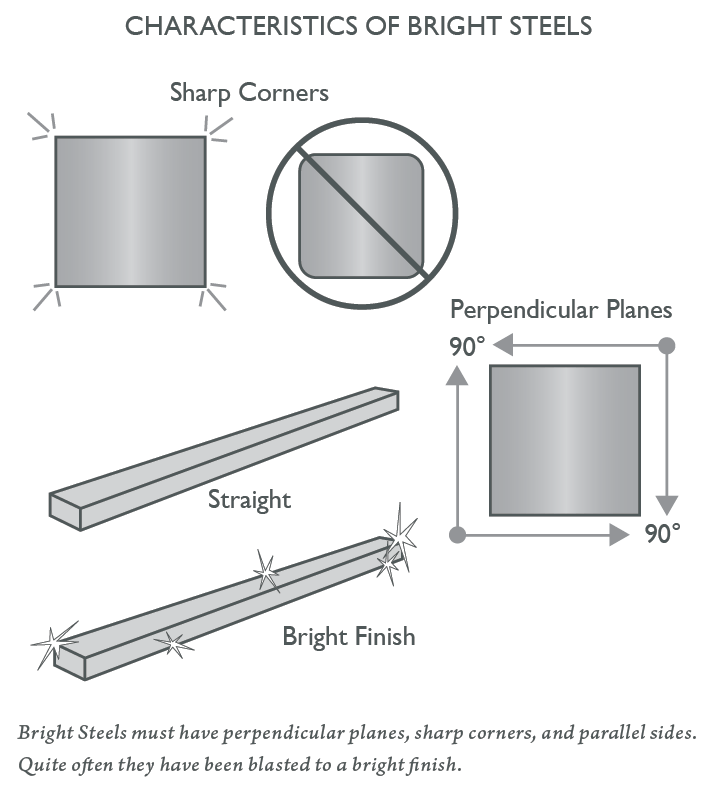

Bright steels typically refer to a class of cold‑finished square and rectangle bars that are drawn to more exacting tolerances; they possess sharp corners, perpendicular and parallel sides, and may be bead blasted to make them “bright.” Bright steels are also known as keystock.

The definitions of keystock and barstock have been elusive because no single standard exists. ANSI sets forth two classes of cold‑drawn steel. Many users of keystock use these specifications in their own product designs, which has led to two problems. First, because ANSI does not specify a grade, there is confusion. Second, most American mills will not produce to the Class 2 fit because the tolerance is too low compared to other cold‑finished forms, and the draw is overly technical. As a result, there is often a difference between what customers want and what is available. Most technicians refer to “barstock” or “key barstock” as cold‑finished material drawn from market‑ready grades to market‑ready tolerances; whereas, “keystock” refers to barstock carefully drawn to ANSI Class 2 fits.

Keystock squares and rectangles are more difficult to draw than rounds because of the 90° angled corners. Bars must be straight and true, and the width must be in a perpendicular plane with the height. The surface finish of keystock must be free of pits and stresses so that installation is smooth and efficient. Most customers prefer sharp corners for increased keyway contact (and minimal rocking), but edges must be sufficiently deburred for ease of use.

Huyett has pioneered the development of new cold‑drawing technologies. Working in concert with steel mills in both the U.S. and abroad, Huyett has put together the most comprehensive line of keystock steel anywhere in the world.

Learn More About Manufacturing at Huyett