Progressive cavity pumps are a type of positive displacement pump commonly used to transport viscous fluids with solids. This guide provides an in-depth overview of the progressive cavity pump, its working principle, advantages, applications, maintenance, and troubleshooting.

1. Working Principle

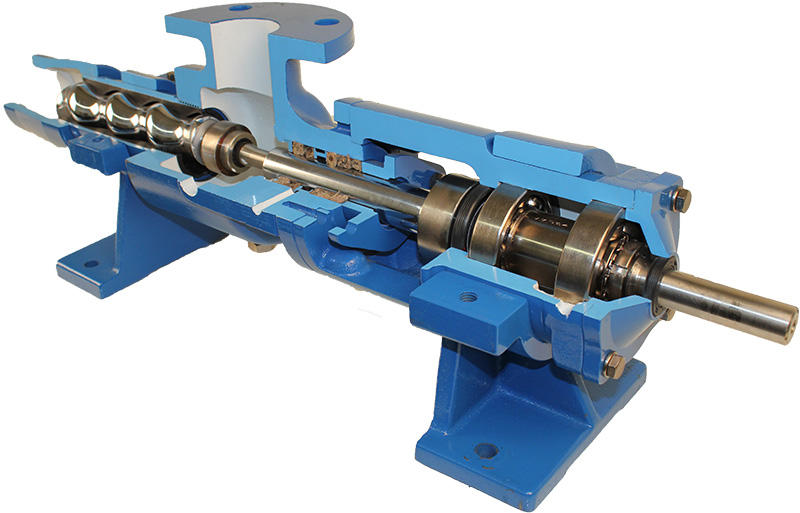

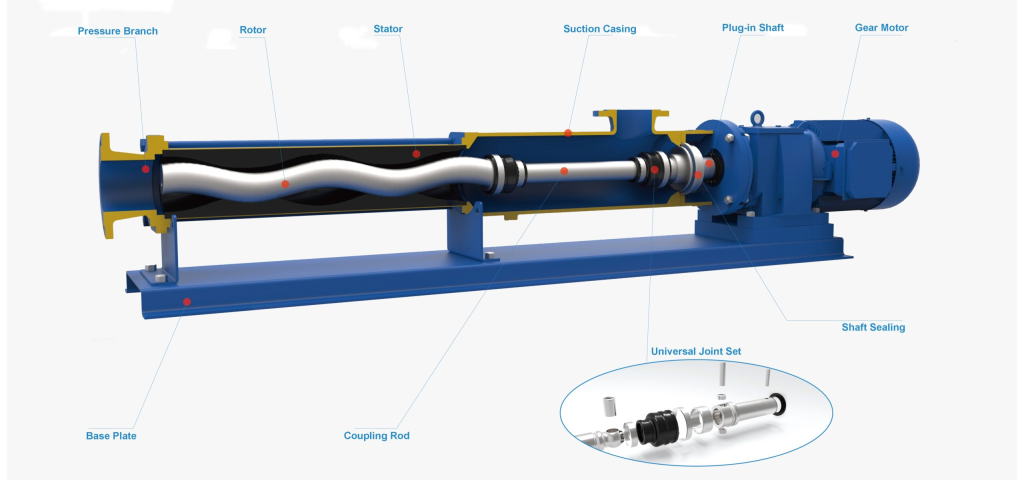

- Design: A progressive cavity pump consists of a single helical rotor that rotates within a double helical stator. The rotor’s rotation creates cavities that move the fluid through the pump.

- Mechanism: As the rotor turns, the fluid is drawn into the cavities formed between the rotor and stator, allowing for smooth and continuous flow. The action of the rotor creates a vacuum that pulls the fluid into the pump.

2. Key Components

- Rotor: A helical screw that rotates to move the fluid.

- Stator: A stationary component that provides a casing for the rotor, typically made of elastomeric material.

- Drive Shaft: Connects the rotor to the motor, allowing for rotation.

- Seals: Prevent fluid leakage and maintain pressure.

3. Advantages

- Versatility: Suitable for pumping a wide range of fluids, including viscous, shear-sensitive, and abrasive materials.

- Smooth Flow: Provides a constant flow rate with minimal pulsation, making it ideal for sensitive applications.

- Self-Priming: Capable of handling low-viscosity fluids and can operate with air or gas entrained in the fluid.

- Durability: Designed to handle abrasive and corrosive materials with appropriate materials of construction.

4. Applications

Progressive cavity pumps are widely used in various industries, including:

- Food and Beverage: Transporting slurries, pastes, and other viscous products.

- Wastewater Treatment: Moving sludge, wastewater, and other thick fluids.

- Chemical Processing: Handling corrosive and hazardous fluids.

- Oil and Gas: Pumping crude oil, drilling mud, and other viscous fluids.

- Pharmaceuticals: Moving shear-sensitive products and formulations.

5. Maintenance

To ensure optimal performance and longevity of progressive cavity pumps, regular maintenance is essential:

- Lubrication: Ensure proper lubrication of moving parts to reduce wear.

- Inspection: Regularly check seals and gaskets for wear and replace as necessary.

- Cleaning: Periodically clean the pump to prevent buildup of materials that could hinder performance.

- Alignment: Maintain proper alignment of the drive shaft to prevent excessive wear.

6. Troubleshooting Common Issues

A. Low Flow Rate

- Possible Causes:

- Clogged inlet or discharge lines.

- Worn rotor or stator.

- Insufficient NPSH (Net Positive Suction Head).

- Solutions:

- Inspect and clean the lines.

- Replace worn components.

- Ensure adequate suction conditions.

B. Excessive Wear

- Possible Causes:

- Pumping abrasive materials.

- Incorrect material selection for rotor and stator.

- Solutions:

- Use wear-resistant materials.

- Regularly monitor and replace worn components.

C. Leakage

- Possible Causes:

- Worn seals or gaskets.

- Improper assembly.

- Solutions:

- Inspect and replace seals as needed.

- Ensure proper assembly during installation.