The production of deep holes can be achieved with many different processes. To create a high-quality final product and keep costs under control, shops must be able to get accuracy, repeatability, and good surface finish while maintaining predictable tool life. Selecting the most appropriate tool for the job and implementing the right operating procedures can improve this difficult operation, making it productive and profitable.

5 Different Deep Hole Drilling Tools and Technologies

Deep hole drilling is the process of machining holes with a depth to diameter ratio of greater than 10:1. Below, we’ll explain 5 deep hole drilling tools and technologies: gundrilling, BTA drilling, ejector drilling, bottle boring tooling and counter boring tooling.

-

Gundrilling

Gundrilling is a deep hole drilling process that uses a long, thin cutting tool to produce holes at high depth-to-diameter ratios. Gundrilling is typically effective in diameters from 1 – 50 mm [~0.04 – 2.00 in]. A gundrill differs from a conventional twist drill by its unique head geometry; a standard gundrill has a single effective cutting edge that removes chips as it advances into the workpiece.

The gundrilling process can drill deep holes beyond what is possible with conventional machinery and tooling, such as twist drills, by using high pressure coolant for clean chip exhaust, even at extreme depths.

There are different types of gundrills, including the following:

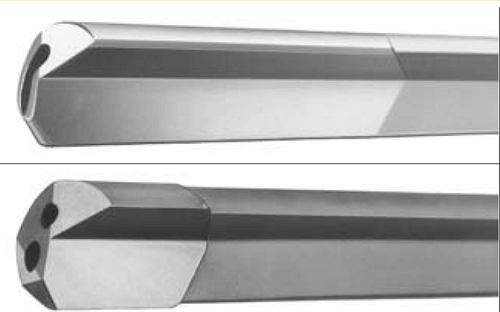

- Single Flute Solid Carbide (g. botek type 110): have one effective flute, which creates unbalanced cutting forces that push the drill away from the cutting action. To overcome this unbalance, gundrills are equipped with built-in guide pads that help create an accurate hole and achieve the desired surface finish. The cutting action pushes the tool and its guide pads against the opposite side of the hole. Various contours and nose geometries are available depending on the application.

- Two Flute (e.g. botek type 120): features two flutes placed 180 degrees apart. This enables the cutting forces to be balanced, keeping the drill tracking straight and helping increase the feed rate.

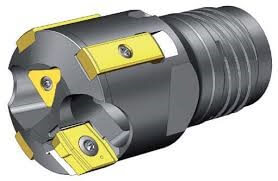

- Indexable (e.g. botek type 01): these gundrills can be single fluted, featuring one screw-down insert with one or more cutting edges and brazed-in or replaceable guide pads; or, they can be two fluted, with multiple insert When used on traditional CNC equipment or on dedicated gundrill machines, indexable gundrills can offer a big advantage in decreased cycle time due to increased cutting data.

For more information about gundrilling, click here.

Source: botek GmbH

-

BTA Drilling

BTA stands for Boring and Trepanning Association and is also sometimes referred to as STS (single tube system) drilling. BTA drilling is a deep hole drilling process that uses a specialized drilling tool on a long drill tube to produce deep holes with a typical diameter of 20 mm [~0.80 in] and larger, and depth-to-diameter ratios of up to 400:1.

BTA drilling heads are threaded and are mounted onto long drill tubes. BTA drilling heads have multiple cutting surfaces to remove chips efficiently, exhausting them using high-pressure metal-working fluid through holes in the tool head, then out the drill tube and through the machining spindle. BTA tooling is available in brazed or inserted carbide configurations.

Source: botek GmbH

-

Ejector Drilling

This system is a variant of the BTA drilling system. Ejector deep-hole drilling is mainly used on conventional machine tools and machining centers; however, unlike BTA deep-hole drilling, there is no sealing to prevent the exit of the metal-working fluid at the workpiece. This drilling system can thus be used if it is not possible to seal the metal-working fluid circuit, e.g. for oblique boring or discontinuous workpieces. Drilling depths of up to 100 x D are possible with this process.

The metal-working fluid is fed through an annular space between the drill tube and an inner tube (double-tube system). The fluid exits from the side of the drilling head, flows over it, and then flows back into the inner tube along with the chips. Some of the fluid is introduced into the inner tube ring nozzle. The resulting underpressure at the chip mouth enables backflow (the ejector effect). An ejector cooling-lubricant feed system is required to generate the ejector effect.

Source: botek GmbH

-

Bottle Boring Tooling

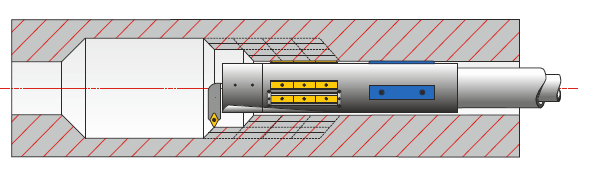

A tool which is used to machine an internal profile within the length of a bore using a cutting insert, which is extended and retracted with CNC capabilities on a BTA-equipped deep hole drilling machine.

Source: BGTB GmbH

Bottle boring tools as an individual tool solution:

- Specific design adaptation to your requirements

- Large feed out stroke ratio (pilot bore to bottle bore inner diameter)

- Maximum stability due to largest possible tool body and due to the lowest guide pad recess

Bottle boring tools as a modular system:

- Multiple setup kits to increase range and different inner diameter configuration of parts

- Ideal guidance in the bore through extension sets

- Simple change of feed out slide

- Flexibility in use of different components

Source: BGTB GmbH

-

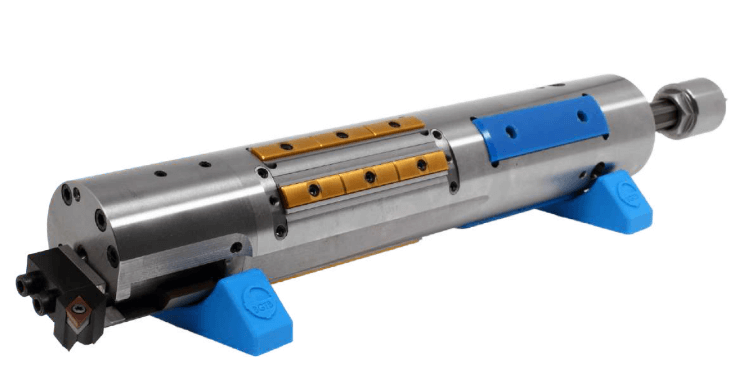

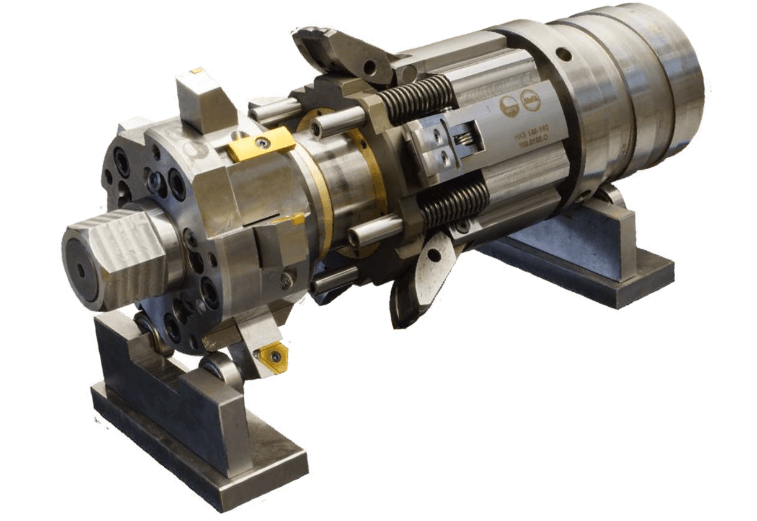

Counter Boring Tooling

A tool that is used to enlarge existing bores by removing stock. This type of tooling is typically used on BTA-equipped deep hole drilling machines.

Advantages of multi-edged counterboring tools include elevated feed rates and improved workpiece quality. Constant wall thickness is often a desired result, which can be achieved by way of tool guidance in the tube (tool follows the pilot hole).

Source: BGTB GmbH

Metal-working fluids are an important part of any deep hole drilling operation, for more information visit our blog “Understanding Metal-Working Fluids for Deep Hole Drilling Operations”.

Our Suppliers

For gundrills, BTA and Ejector drilling, Triumph Tool proudly represents botek, the world market leader in the field of single flute gundrills. Please contact us to learn more about how botek’s over 40 years of experience in deep hole drilling and applications can benefit you.

For Bottle Boring and Counter Boring tools, we are proud to represent BGTB GmbH, a German manufacturer specialized in the conception, design and manufacture of complete bottle boring systems for machining non-cylindrical inner contours.

To learn more about these and other innovative solutions, or to get in touch with our in-house Deep Hole Drilling Product Manager, please contact us.