Gundrilling is a deep hole drilling practice that utilizes a long, thin cutting tool to create holes at high depth-to-diameter ratios. These tools are available in three basic configurations: carbide tipped, solid carbide and indexable carbide.

What Are Gundrills?

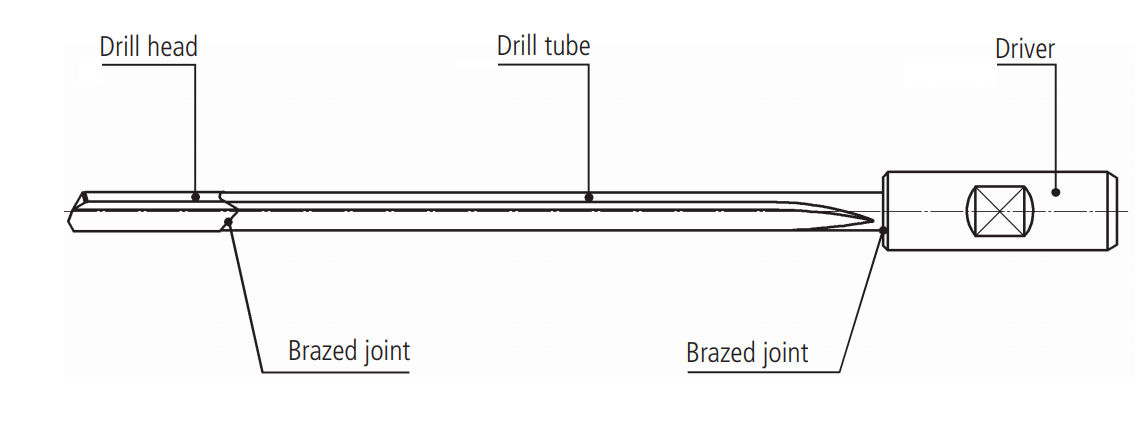

Gundrills are known for generating long, straight, close tolerance holes with exceptional surface finish at a high penetration rate. Carbide gundrills are typically used when the hole depth The picture below represents a standard carbide tipped single flute gundrill.

A gundrill diverges from a regular twist drill by its distinctive head geometry. A standard gundrill has a single effective cutting edge that removes chips as it advances into the workpiece. The gundrilling process can drill deep holes past what is possible with conventional machinery and tooling like twist drills, by utilizing high pressure coolant for clean chip removal, even at extreme depths.

These deep hole drilling tools hold location to accurate tolerances, generate burr-free holes, and are sized to precise specifications. They can also be formed, with Additionally, this operation creates accurate, repeatable holes with outstanding surface finishes, which eliminates the need for one or more secondary or finishing operations.

Gundrills are easily integrated with CNC machining centers, lathes and milling machines for a reasonably small investment, which makes these tools affordable for small or large shops with varying production requirements.

Gundrill Configurations

Solid carbide gundrills offer high performance, process reliability and longer tool life in many applications due to the reduced torsional vibration and higher rigidity.

Indexable carbide gundrills also offer many benefits, such as the increased tool life due to full coating, indexable design and edge treatment. This design reduces downtime with the quick replacement of worn parts, and versatility for use on machining centers, deep hole machines and lathes.

Gundrills are available in both single-flute and two-flute configurations. Two-flute gundrills are usually the best choice for drilling aluminium or cast iron, as these can be run at twice the penetration rate of single flutes. In the single flute gundrilling process, the coolant is fed through the coolant hole in the tool and exits along with the chips in the V-shaped groove (flute) on the drill tube from the drilled hole.

Benefits of gundrilling

- High cutting performance;

- Minimum centreline deviation;

- Outstanding drilling quality (surface, drilling tolerance);

- High process reliability through trouble-free chip removal;

- Suitable for minimum quantity lubrication (MQL).

Our gundrill supplier

Triumph Tool proudly represents botek, the world market leader in the field of single flute gundrills. Please contact us to learn more about how botek’s over 40 years of experience in deep hole drilling and applications can benefit you.